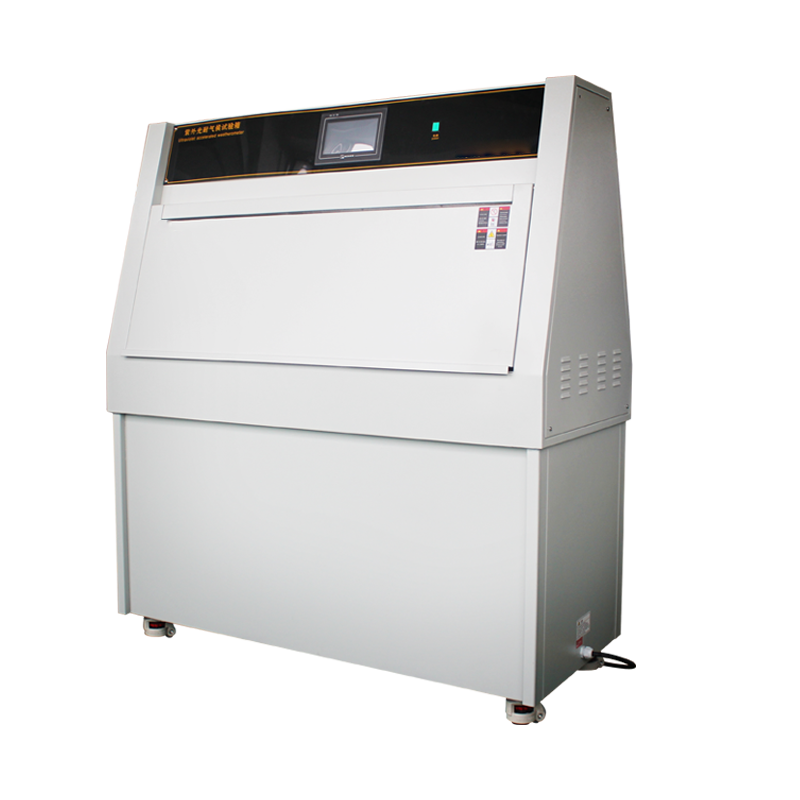

A UV aging test chamber is a crucial piece of environmental testing equipment widely used in industries such as materials, coatings, plastics, rubber, and electronics. It simulates the effects of ultraviolet (UV) radiation from the natural environment on products, accelerating the aging process to predict service life and performance changes. But how closely do these chambers actually mimic real-world conditions? And what key data points in the test reports are most important to focus on?

The Principle Behind Simulating Real Environments

UV aging test chambers primarily simulate environmental factors like UV radiation, temperature, and humidity from sunlight to accelerate the photochemical degradation of materials. By adjusting radiation intensity, temperature cycles, and humidity levels, these chambers create harsh yet controllable conditions, allowing samples to undergo aging damage in a short time that would typically take years in real-world use.

However, there are differences between the chamber and natural conditions. For instance, natural sunlight has a cyclical pattern and a full spectrum of light, while the UV lamps in test chambers often have a more singular and stable spectral output. Consequently, accelerated testing results are better at predicting trends and relative changes rather than providing an absolute equivalent to a specific natural environment.

Advantages of UV Aging Test Chambers

- High Controllability: Precise control over UV intensity, temperature, and humidity ensures test repeatability.

- Time Acceleration: Significantly shortens the material aging process, enabling rapid assessment of weatherability.

- Cost-Effectiveness: Saves the time and expense associated with long-term outdoor exposure testing.

- Versatile Simulation: Supports various environmental cycle modes, better approximating variable outdoor conditions.

What Key Data Should a Test Report Include?

A comprehensive UV aging test report should detail the test conditions and the resulting changes in product performance, helping to scientifically evaluate a material's resistance to aging. Key data points include:

- Irradiance Level: The intensity of UV radiation (usually in W/m²), which directly impacts the aging rate.

- Test Temperature and Humidity: Includes temperatures near the lamps, black panel temperature, and relative humidity, reflecting the influence of thermal and moisture conditions on material aging.

- Light/Dark Cycle Times: Describes the on/off cycle ratio of the UV lamps, simulating the stress of day/night alternation on materials.

- Total Exposure Time: The duration of the test in hours, which determines the degree of aging.

- Performance Change Data: Quantitative metrics like color difference (ΔE), changes in tensile strength, elongation at break, and surface morphology changes, illustrating the extent of photodegradation.

- UV Spectral Distribution: Confirms the wavelength range of the light source used, ensuring relevance to real-world UV wavelengths.

- Test Standards and Methodology Reference: The national or international standards followed (e.g., ISO, ASTM), ensuring the authority and comparability of the results.

While a UV aging test chamber cannot perfectly replicate the full complexity of the natural environment, it serves as a vital tool for verifying and predicting material weatherability through its highly controlled and accelerated UV aging tests. When combined with detailed key data from test reports, it empowers businesses to optimize material design, enhance product quality, and boost market competitiveness.