| Sizes of Thermal Shock Chambers |

|

Model

|

Volume (L)

|

Temperature Shock Range(°C)

|

Rated Power

|

Internal Dimension (mm) D*W*H

|

External Dimension (mm) D*W*H

|

|

LRHS-101A-LV

|

101

|

A:-40°C~150°C

B:-55°C~150°C

C:-65°C~150°C

|

17.0kW

|

450*450*500

|

1700*930*1650

|

|

LRHS-150A-LV

|

150

|

22.0kW

|

500*600*500

|

1800*1080*1650

|

|

LRHS-234A-LV

|

234

|

25.0kW

|

600*600*650

|

1950*1080*1950

|

|

LRHS-512A-LV

|

512

|

53.0kW

|

800*800*800

|

2950*1450*2250

|

|

LRHS-753A-LV

|

753

|

72.0kW

|

970*970*800

|

3130*1620*2250

|

|

LRHS-1000A-LV

|

1000

|

95.0kW

|

1120*1120*800

|

3300*1780*2250

|

Note: In the Model, the number means volume of test chamber's working room, and ABCD means the temperature range.

For example, model LRHS-101A-LV means the volume of this test chamber is 101L, and its temperature shock range is -40°C~+150°C. LRHS-234C-LV means the volume is 234L and the temeprature shock range is -65°C~+150°C |

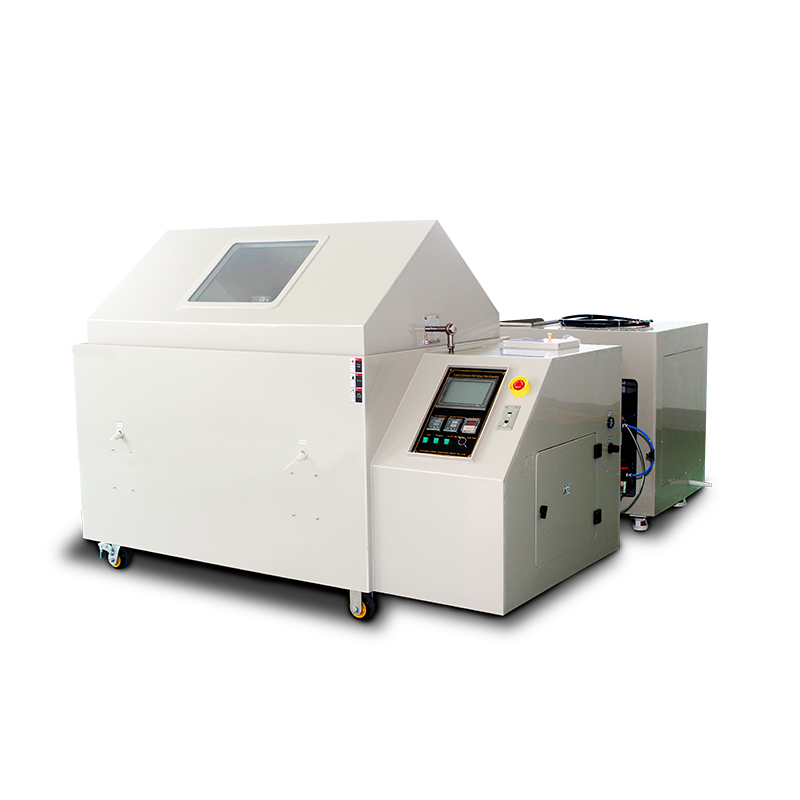

| Basic Specification |

|

Performance

|

Temperature Shock Range |

A:-40°C~150°C B:-55°C~150°C C:-65°C~150°C |

| Temperature Fluctuation |

±1°C |

| Ramp Rate |

Heating: RT~150°C ≤25min

Cooling: RT~ -55°C ≤45min

Note: can be customized as per requirement |

| Basket Size |

250×250×250mm(100L) 600×600×500mm(512L)

300×400×250mm(150L) 760×760×500mm(753L)

400×400×400mm(234L) 920×920×500mm(1000L) |

| Temperature Recovery Time |

≤5min |

| Basket Change Time |

≤15s |

|

Material

|

External Casing |

Cold-rolled A3 (Q235) steel plates with plastics painted. |

| Interior Working Room |

Stainless Steel Plates SUS304 with miror surface |

| Heat Isolation |

Polyurethane foams and fine glass fibres |

| Illumination Lamp |

Philips® one in per standard test chamber. |

| Casters |

4pcs, with PU covered for protection. Height adjustable and direction universal. |

| Door |

Manually operated sliding door with unl°Ck button |

|

Heating & Cooling System

|

Heater |

Steipped Nickel-chromium Wire Heater |

| Air Blower |

Anti-temperature stainless fan blades with low noise |

| Compressor |

Hermetically-sealed Techmesh® or semi-sealed Bitzer® or GEA® or equivalent compressors |

| Cooling Method |

Single or dual cooling (Air-cooled or Water-cooled) |

| Refrigerant |

R404A or/and R23 (eco-friendly) |

| Condenser |

Plate-type heat exchanger |

|

Control System

|

Controller |

7" Programmable colorful touch-screen display

LCD English Display

Micr°Computer integrated controller |

| Functions |

Data Record (Max 600 days x 24hrs), History Curve, USB data download & upload, Remote controlling through PC, Automatic protection alarms, etc. |

| Program |

1~1000 programs, 1~999 steps for per program, Max 99hrs 59mins for per program. 10 programs can be interlinked. |

| Temperature Sensor |

Platinum Resistance.PT100Ω |

| Running Model |

Constant/Fix-value Model and Programmable Model |

| I/O Interface |

Communicate port (RS485) to connect test chamber to a PC |

| Standard Configuration |

Test Chamber x 1, Specimen Holder Shelf x 2, φ100mm Cable Access Port x 1 with 1 soft plug, EMO x 1, Tri-color Indicator x 1, etc. |

| Safety Protection |

Power leakage protection/Compressor over-heat, over-load or over-current protection/Dry burning protection. |

| Voltage |

380V/440V±10%, 50Hz/60Hz or as per requirement |

| Ambient Enviromental for application |

5°C~+30°C ≤ 85%R.H |

| Test Standards (not limited to) |

IEC60068-2-1

IEC60068-2-2

IEC60068-2-78

IEC60068-2-30

|