With the rapid development of new energy vehicles and portable electronic devices, aluminum batteries have become a key focus for research and application in the industry due to their advantages such as lightweight, high energy density, and environmental friendliness. In practical use, aluminum batteries often face complex and variable environmental conditions, particularly exposure to rain, which imposes stringent requirements on their safety and performance stability. The advent of the rain test chamber addresses this critical challenge, ensuring product quality, safety, and reliability.

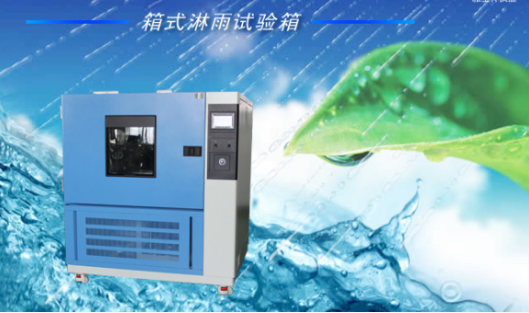

A rain test chamber is a specially designed device that simulates working conditions in rainfall environments. It tests the waterproof performance of batteries by creating an artificially controlled rain-like setting. It can simulate rainfall scenarios of varying intensities to inspect the integrity of a battery’s waterproof sealing structure and verify whether the battery continues to function normally after water ingress.

Testing Methods for Aluminum Battery Rain Test Chambers

Test Preparation

First, place the aluminum battery or battery pack to be tested into the rain test chamber, ensuring the battery is in normal power supply or standby mode. Select an appropriate fixation method based on the battery specifications to prevent movement during testing.

Setting Test Parameters

According to relevant standards (e.g., GB/T 2423.38-2008, IEC 60068-2-18), set parameters such as rainfall intensity (e.g., water flow rate), spray angle, and test duration to ensure the simulated environment matches real-world conditions.

Initiating the Rain Test

Start the equipment to allow water to spray evenly onto the battery surface. Observe and record changes in voltage and current, as well as any potential abnormalities during the test.

Post-Test Inspection

After the test, inspect the battery for any external damage or compromised sealing performance. Conduct electrical performance tests to confirm the battery’s functionality remains unaffected. If the equipment supports it, further tests such as internal short-circuit and insulation performance checks can be performed.

Advantages of Aluminum Battery Rain Test Chambers

- Highly Realistic Simulation: Adjustable water flow intensity and spray angles enable multi-angle, multi-mode testing of waterproof performance.

- Enhanced Product Reliability: Early detection of waterproof defects prevents safety hazards during user operation.

- Cost and Time Efficiency: Automated controls minimize human error and improve testing efficiency.

- Multi-Functional Integration: Some rain test chambers support combined temperature and humidity testing, enhancing scientific accuracy.

Applications

- Performance validation of aluminum batteries for new energy vehicles

- Quality control of aluminum batteries in portable electronic devices

- Waterproof performance development in R&D laboratories

- Quality inspection of finished products in battery manufacturing

The aluminum battery rain test chamber, with its precise environmental simulation and scientific testing methods, has become an essential tool for ensuring waterproof performance. Choosing professional rain testing equipment is not only key to improving product quality but also a crucial factor in gaining market and user trust. If you are seeking an efficient and reliable waterproof testing solution for aluminum batteries, the aluminum battery rain test chamber is your ideal choice.