In today's competitive global market, product reliability is non-negotiable. Consumers expect durability, whether they're purchasing electronics, automotive parts, or outdoor equipment. But how do manufacturers ensure their products withstand harsh weather conditions? The answer lies in an often-overlooked yet essential tool: the rain test chamber.

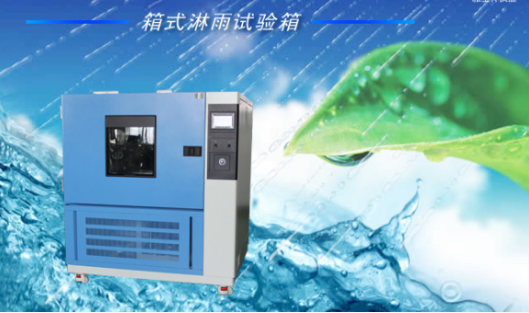

This advanced testing equipment simulates rainfall and water exposure, helping companies identify weaknesses before products reach consumers. Far from being just another piece of lab machinery, rain test chambers act as "invisible guardians"—silently ensuring quality, safety, and compliance with international standards.

The Science Behind Rain Test Chambers

Rain test chambers (also called water spray test chambers or weather resistance testers) replicate natural rainfall conditions in a controlled environment. They evaluate how products react to water exposure—whether through dripping, spraying, or heavy downpour simulations.

Key Testing Parameters:

- Water Intensity – Adjustable spray nozzles simulate light drizzle to torrential rain.

- Temperature Control – Some tests combine water exposure with extreme temperatures.

- Duration & Cycles – Products undergo prolonged or repeated exposure to mimic real-world use.

- Angled Spray Testing – Ensures water resistance from multiple directions.

By subjecting products to these conditions, engineers can detect leaks, corrosion, electrical failures, and material degradation—before customers encounter them.

Industries That Rely on Rain Testing

1. Automotive Industry

Cars face relentless exposure to rain, snow, and road spray. Faulty seals or electrical components can lead to costly recalls.

How Rain Test Chambers Help:

- Verify windshield wiper efficiency.

- Test door and window seals for leaks.

- Ensure electronic systems (e.g., sensors, infotainment) remain functional in wet conditions.

Example: A leading car manufacturer avoided a major recall by detecting a faulty sunroof drainage system during rain chamber testing.

2. Electronics & Consumer Devices

From smartphones to outdoor security cameras, water resistance is a major selling point.

How Rain Test Chambers Help:

- Validate IP (Ingress Protection) ratings (e.g., IP65, IP67).

- Prevent internal circuit damage from moisture.

- Ensure touchscreen functionality remains intact.

Fact: Smartphones advertised as "water-resistant" undergo rigorous rain and immersion tests.

3. Aerospace & Defense

Aircraft components must endure extreme weather without failure.

How Rain Test Chambers Help:

- Test avionics systems against heavy rain and humidity.

- Evaluate material durability under prolonged moisture exposure.

- Ensure emergency equipment (e.g., life rafts) remains functional.

4. Building Materials & Construction

Windows, roofing, and exterior cladding must resist water penetration for decades.

How Rain Test Chambers Help:

- Simulate wind-driven rain to test structural integrity.

- Identify weak points in waterproof membranes.

- Prevent mold growth by detecting moisture ingress.

The Cost of Skipping Rain Testing

Ignoring water resistance testing can lead to:

- Product Recalls – Expensive and damaging to brand reputation.

- Safety Hazards – Electrical failures in wet conditions can be deadly.

- Customer Dissatisfaction – Water-damaged products lead to returns and negative reviews.

- Non-Compliance Fines – Many industries mandate water resistance certifications.

Case Study: A solar panel manufacturer faced massive losses after untested panels leaked during monsoon seasons, voiding warranties.

Choosing the Right Rain Test Chamber

Not all chambers are equal. Key considerations include:

- Customization – Can it simulate your product’s real-world conditions?

- Automation – Does it offer programmable test cycles?

- Compliance – Does it meet ISO, IEC, or MIL-STD standards?

- Durability – High-quality chambers last longer with minimal maintenance.

Tip: Look for chambers with real-time monitoring and data logging for precise analysis.

Rain test chambers may operate behind the scenes, but their impact is undeniable. They prevent failures, save costs, and build consumer trust—making them true "invisible guardians" of product quality.

For manufacturers aiming to deliver reliable, weather-resistant products, investing in advanced rain testing isn’t optional—it’s essential.