In a hyper-competitive marketplace, reliability is no longer a “nice-to-have”—it is the foundation on which brands are built. Every manufacturer wrestles with the same challenge: how to guarantee that a product’s performance and appearance remain intact after months or even years in the field. Over the past decade, the UV-weathering chamber has quietly become the go-to tool for answering that question.

What is a UV-weathering chamber?

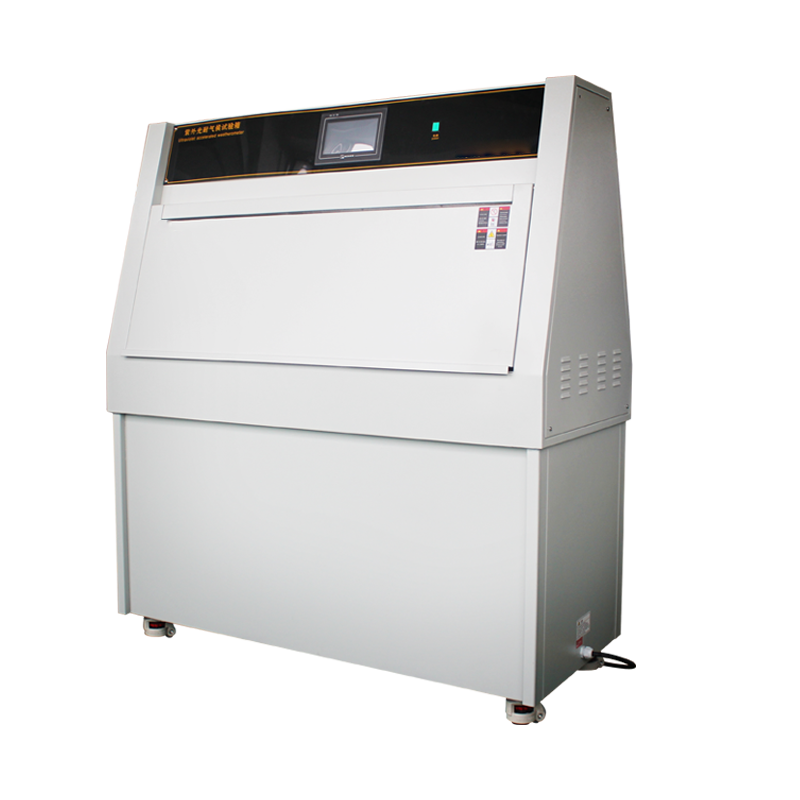

A UV-weathering chamber replicates the full spectrum of threats a product faces outdoors: ultraviolet light, heat, and humidity. By accelerating these conditions, the chamber exposes materials to years’ worth of weathering in a matter of days or weeks. The result is fast, precise insight into a product’s UV-stability, colorfastness, and overall durability.

A UV-weathering chamber replicates the full spectrum of threats a product faces outdoors: ultraviolet light, heat, and humidity. By accelerating these conditions, the chamber exposes materials to years’ worth of weathering in a matter of days or weeks. The result is fast, precise insight into a product’s UV-stability, colorfastness, and overall durability.

How it drives reliability

-

Catch problems before customers do

Early-stage testing reveals cracks, chalking, color fade, or embrittlement long before mass production starts. Engineers can reformulate resins, tweak pigments, or adjust processing parameters before a single unit ships. -

Choose the right material—every time

Run side-by-side tests on competing substrates, coatings, or additives and obtain hard data on which option survives the longest. Eliminate guesswork and design products that outlast the competition. -

Earn customer trust with proof

A detailed test report showing 1,000 hours of Q-UVB exposure with zero ΔE color shift speaks louder than any marketing claim. Customers notice—and remember. -

Meet or exceed global standards

ASTM, ISO, SAE, and countless OEM specs all reference accelerated UV testing. Passing these tests up front prevents costly recalls or field retrofits later. -

Turn data into tomorrow’s design rules

The degradation curves generated in the chamber feed directly into FEA models and predictive life calculations, so the next product generation starts with a built-in reliability advantage.

A UV-weathering chamber is more than a test device; it is an insurance policy for your brand. It identifies weak links, validates superior materials, and delivers the evidence today’s buyers demand. Make reliability your signature—and let the chamber do the proving.