In the electronics manufacturing industry, PCBs (Printed Circuit Boards) serve as one of the core components, and their quality stability directly impacts the performance and lifespan of the final product. As electronic products evolve toward higher performance and greater reliability, traditional aging testing methods struggle to meet the demands of harsh environmental conditions. In this context, UV aging test chambers have emerged as a revolutionary tool for PCB aging testing, safeguarding product quality.

Why Choose UV Aging Test Chambers for PCB Aging Testing?

In real-world applications, PCBs are often exposed to sunlight UV radiation, fluctuating temperatures, and humid environments. Prolonged UV exposure can lead to material degradation, solder pad detachment, circuit corrosion, and even electrical performance deterioration. UV aging test chambers simulate natural UV radiation as well as temperature and humidity variations, accelerating environmental aging to precisely replicate PCB performance under extreme conditions. This enables companies to identify potential product defects early, avoiding significant financial losses caused by quality issues later on.

Practical Advantages of UV Aging Test Chambers in PCB Testing

1. Accurate Simulation of Natural UV Environments

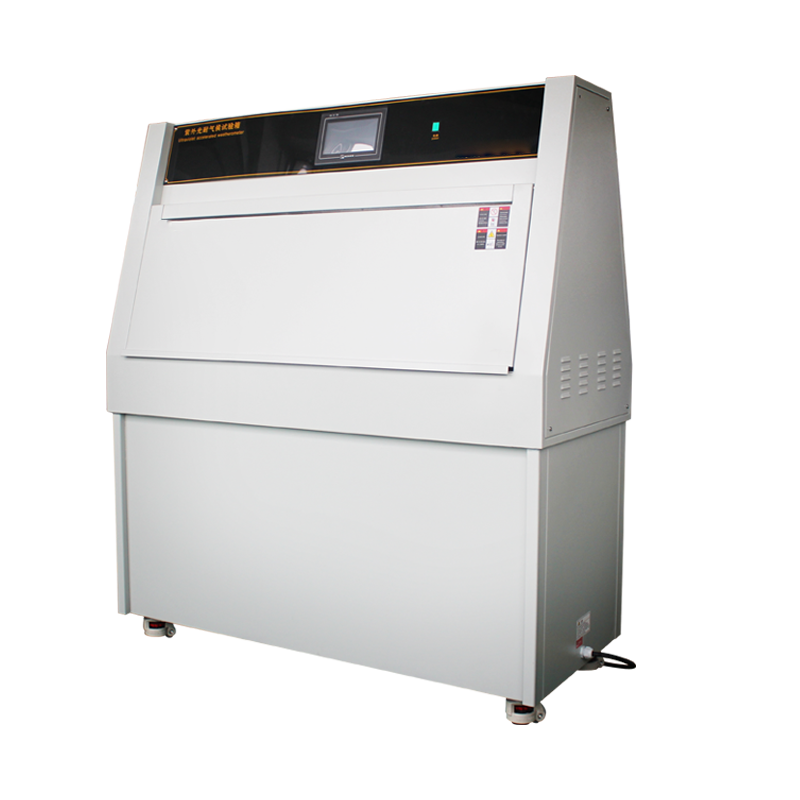

Equipped with high-intensity UV light sources, these chambers simulate full-spectrum solar UV radiation, ensuring more realistic testing and reliable data.

2. Accelerated Aging Process, Shortened Testing Cycle

While traditional natural aging takes months or even years, UV aging test chambers can complete equivalent aging tests in just a few days, significantly improving R&D and quality inspection efficiency.

3. Multi-Environmental Compound Testing Conditions

The equipment allows for adjustable parameters such as temperature, humidity, and UV exposure cycles, simulating complex environments where high temperatures, humidity, and UV radiation coexist. This ensures a comprehensive evaluation of PCB durability.

4. High Repeatability and Stability

Precise control systems guarantee consistent testing conditions across batches, facilitating product optimization, process improvements, and overall quality control.

Real-World Application Case Study

A leading electronics manufacturer introduced UV aging test chambers and conducted multi-batch aging tests on critical PCB products. The tests revealed issues such as solder joint cracks and micro-fractures in circuits. Leveraging the test data, the company optimized material selection and soldering processes, extending product lifespan by 30% and reducing repair rates by 15%. This significantly enhanced customer satisfaction and market competitiveness.

In the fiercely competitive electronics market, quality is the lifeline of any enterprise. UV aging test chambers not only provide scientific support for PCB aging testing but also represent a qualitative leap forward. They are an indispensable tool for developing highly reliable electronic products, serving as a solid foundation for quality control and innovation-driven upgrades.