A UV aging test chamber is primarily used to simulate the aging process of materials under ultraviolet (UV) light exposure, helping to evaluate the weather resistance and durability of materials. Below are some common test items:

A UV aging test chamber can perform a variety of tests, mainly including the following aspects:

Weather Resistance Testing: The UV aging test chamber simulates conditions such as UV radiation, temperature, humidity, condensation, and spray found in natural sunlight to conduct accelerated weathering tests on materials. This evaluates the material's weather resistance over long-term use, including issues like fading, cracking, and peeling.

Coating Testing: In the paint and coatings industry, the UV aging test chamber is used to test the weather resistance and UV resistance of coatings, assessing issues such as fading, peeling, and cracking in outdoor environments.

Plastic and Rubber Material Testing: The test chamber can simulate the aging process of plastic and rubber materials under sunlight and natural environments, evaluating their physical and chemical changes to ensure stability and reliability during long-term use.

Automotive Industry Testing: In the automotive industry, the UV aging test chamber is used to test the weather resistance of interior and exterior automotive components, ensuring the stability and reliability of parts over long-term use.

Electronics Industry Testing: It evaluates the UV resistance of electronic product casings and components, ensuring durability and reliability in outdoor environments.

Photovoltaic Industry Testing: It simulates the aging process of photovoltaic modules in outdoor environments, assessing their performance and reliability over long-term use.

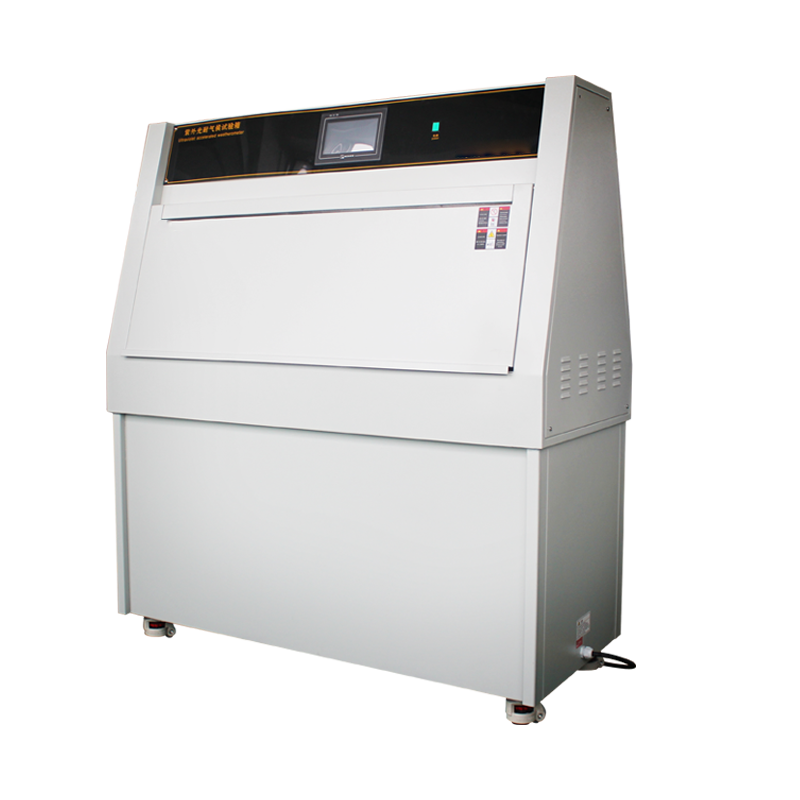

Working Principle of the UV Aging Test Chamber: The chamber uses fluorescent UV lamps as the light source to simulate UV radiation, temperature, humidity, condensation, and spray conditions found in natural sunlight, conducting accelerated aging tests on materials. The equipment can precisely control parameters such as temperature, humidity, and radiation intensity to ensure the reliability and repeatability of test results.

Through these tests, manufacturers and researchers can gain insights into the long-term performance of materials, providing important data for product improvement and development.