In the fiercely competitive market, product quality has become a critical factor for the survival and growth of enterprises. Any seemingly minor quality weakness may manifest in extreme environments during actual use, affecting brand reputation and customer satisfaction. So, how can these hidden risks be identified and addressed in advance? The UV aging test chamber has emerged as a powerful tool for evaluating product quality.

What is a UV Aging Test Chamber?

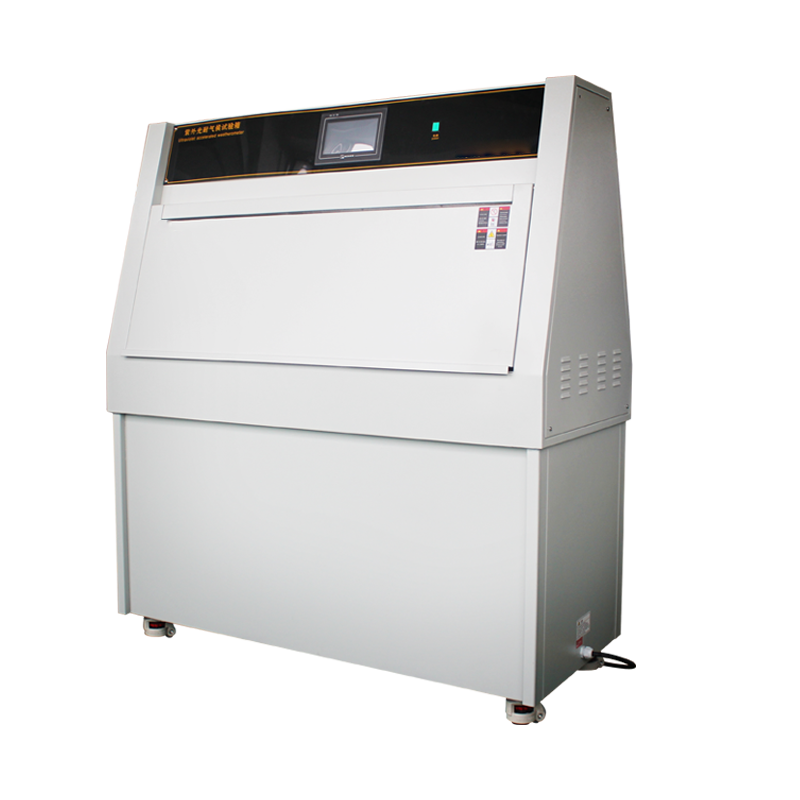

The UV aging test chamber simulates ultraviolet light exposure, temperature fluctuations, and humidity changes in natural environments to rapidly replicate the aging process of products under sunlight exposure. It not only reveals phenomena such as discoloration, cracking, chalking, and peeling in materials or products within a short period but also provides businesses with scientific data references for weather resistance.

How Does the UV Aging Test Chamber Reveal "Quality Weaknesses"?

Many products perform well under normal testing conditions, but when subjected to high-intensity UV radiation, weaknesses in aging resistance become apparent. The UV aging test chamber achieves this by:

Extreme Environment Simulation: Recreating intense UV radiation and temperature cycles to quickly expose hidden material fatigue and deterioration issues.

Accelerated Aging Process: Compressing months, years, or even longer real-world usage cycles into just days or even hours of testing.

Quantitative Durability Assessment: Helping R&D and quality teams precisely identify weak points in product performance, enabling targeted improvements in design and material selection.

Leveraging the UV Aging Test Chamber to Enhance Corporate Competitiveness

Reduce Post-Sale Risks: Identify potential quality issues early to minimize customer complaints and returns, safeguarding brand reputation.

Shorten R&D Cycles: Quickly obtain weather resistance validation to accelerate the launch of new products.

Optimize Product Design: Use scientific data to guide precise material selection and process improvements, enhancing product durability and user experience.

Facing increasingly stringent market quality standards, businesses need a "magnifying glass"-level testing tool to uncover hidden quality weaknesses. The UV aging test chamber is precisely this tool, exposing "quality weaknesses" in extreme environments, thereby helping enterprises achieve quality upgrades and develop more competitive, high-quality products.