Corrosion is a common challenge in the electrical, instrumentation, and new energy industries, and salt spray test chambers play a key role in addressing this issue.

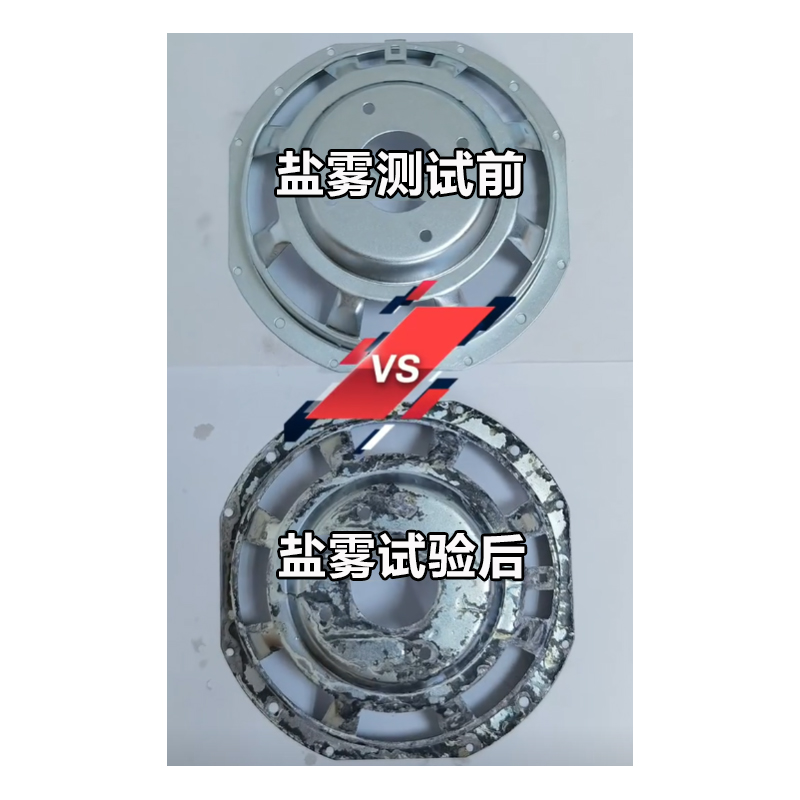

A salt spray test chamber is a specialized device designed to simulate high-concentration salt mist environments, such as those found in marine climates. It generates a saltwater solution and sprays it onto test specimens, accelerating the corrosion process under high-salt conditions in a relatively short time. This allows for the evaluation of materials and equipment's corrosion resistance.

Applications in the Electrical Industry

Many electronic components and circuit boards must operate in harsh environments, such as offshore wind farms, coastal regions, or high-humidity areas—where salt mist can cause corrosion and failure. By using salt spray test chambers, manufacturers can conduct reliable corrosion resistance tests on electronic components and circuit boards to ensure their durability and stability in extreme conditions.

Applications in the Instrumentation Industry

Precision instruments and measuring devices often require long-term operation with high accuracy and reliability. However, humidity and salt mist can corrode and damage these instruments. Testing in salt spray chambers simulates these harsh conditions, allowing manufacturers to assess corrosion resistance and stability, identify potential issues early, and implement preventive measures.

Applications in the New Energy Sector

The development of solar, wind, and other renewable energy technologies relies on extensive use of metal materials and equipment. Many of these systems operate in marine or high-humidity environments, making them vulnerable to salt-induced corrosion. Salt spray testing helps evaluate the corrosion resistance of materials and equipment, ensuring long-term reliability and performance in demanding conditions.

Salt spray test chambers play a crucial role in the electrical, instrumentation, and new energy industries. They enable the assessment of materials and equipment under corrosive conditions, helping detect potential issues early and implement corrective measures to ensure operational reliability. By leveraging this technology, industries can enhance product durability and maintain performance in challenging environments.