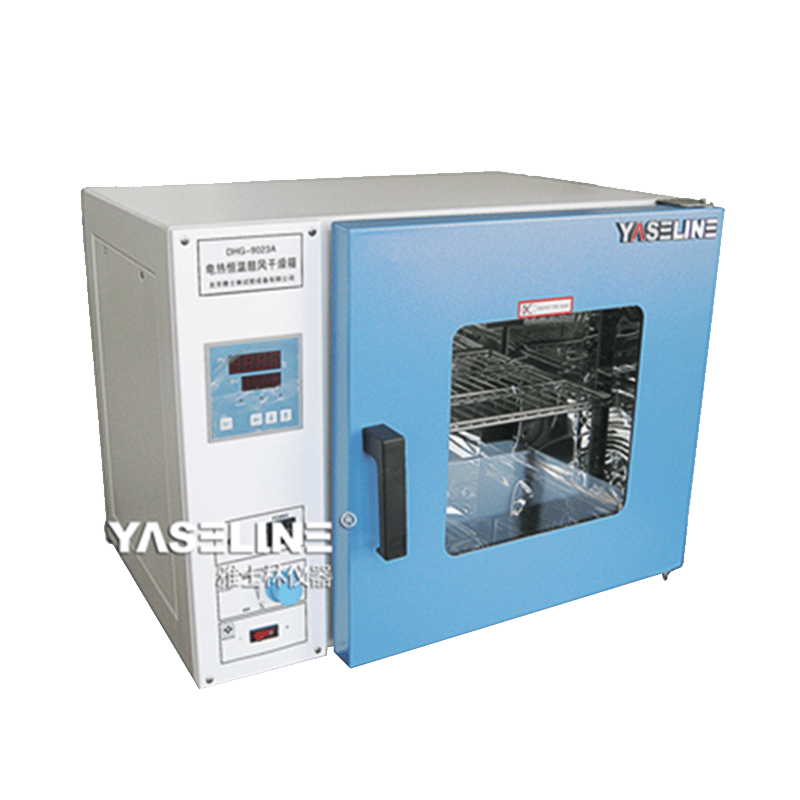

A forced air drying oven is a commonly used drying equipment, typically employed in industrial production and laboratory research. It utilizes a forced air method, circulating air through an internal fan to accelerate the drying process of objects.

A forced air drying oven is a commonly used drying equipment with the following characteristics:

-

Efficient Drying: The forced air drying oven is equipped with a forced air device that circulates air through a fan, speeding up moisture evaporation and the drying process of items, thereby improving drying efficiency.

-

Uniform Drying: The internal fan of the forced air drying oven evenly distributes hot air to all corners, ensuring uniform drying of both the surface and interior of items, preventing localized over-drying or excessive moisture.

-

Temperature Control: The forced air drying oven allows users to set the desired temperature range. By adjusting the heating element, the temperature of the hot air inside the oven can be controlled to meet the drying requirements of different items.

-

Adjustable Humidity: Some advanced forced air drying ovens are equipped with humidity control devices, enabling the adjustment of internal humidity levels as needed to accommodate the humidity requirements of various items.

-

Versatile Applications: The forced air drying oven can be used for drying a wide range of items, such as laboratory equipment, food, pharmaceuticals, cosmetics, etc., making it suitable for a broad spectrum of uses.

-

Monitoring and Safety: Some advanced forced air drying ovens feature real-time temperature and humidity monitoring systems. These systems track environmental changes inside the oven and provide timely alerts in case of abnormalities, ensuring safety during use.

In summary, the forced air drying oven, through its circulating fan and temperature control, enables rapid and uniform drying of items and offers versatile application features.