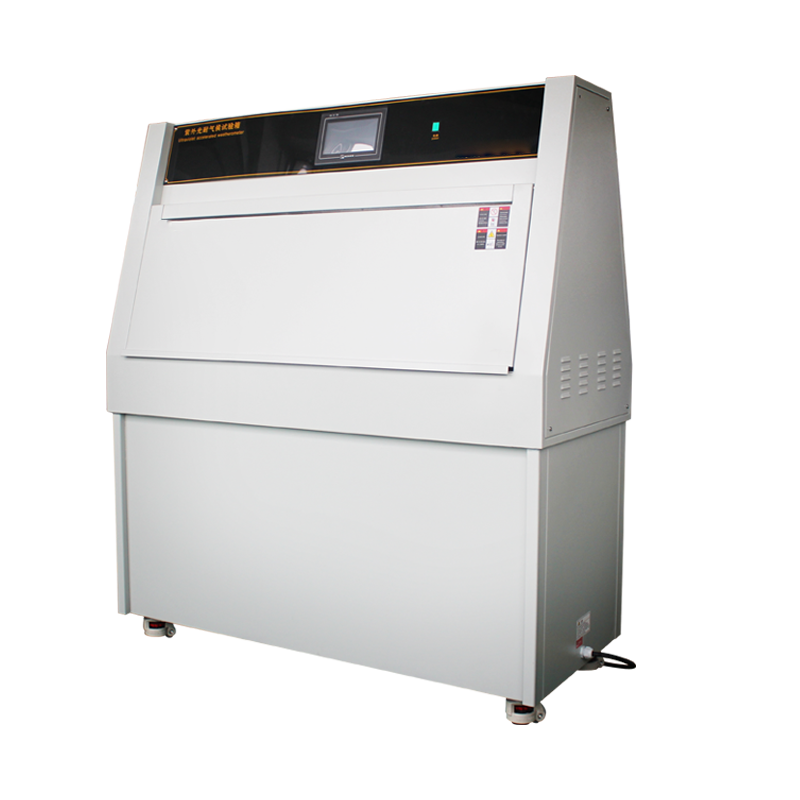

The reliability and performance of UV aging test chambers are critical for industries requiring accurate simulation of environmental conditions to evaluate material durability. These chambers are designed to replicate the effects of sunlight, moisture, and temperature fluctuations, making them indispensable in sectors such as automotive, aerospace, coatings, and plastics. The assurance of quality in these systems is paramount, as it directly impacts the validity of test results and, consequently, product longevity and safety.

Key Factors Influencing Quality Assurance

1. Compliance with International Standards

High-quality UV aging test chambers adhere to internationally recognized standards such as ISO 4892, ASTM G154, and SAE J2020. These standards define precise parameters for UV exposure, temperature control, and humidity levels, ensuring consistency and reproducibility across tests. Manufacturers that certify their equipment under these guidelines provide users with confidence in the accuracy and reliability of their testing processes.

2. Precision in UV Light Simulation

The spectral output of UV lamps must closely match natural sunlight, particularly in the UV-A (315–400 nm) and UV-B (280–315 nm) ranges. Premium test chambers utilize fluorescent lamps with tightly controlled wavelength distributions to avoid deviations that could compromise test results. Regular calibration and lamp replacement protocols further maintain spectral accuracy over time.

3. Advanced Control Systems

Modern UV aging chambers incorporate sophisticated microprocessor-based controls to regulate temperature, humidity, and irradiance levels with minimal fluctuation. Features such as real-time monitoring, automated adjustments, and data logging enhance repeatability while reducing human error. Systems equipped with fail-safe mechanisms and alarms ensure uninterrupted operation, even in extended testing scenarios.

4. Robust Construction and Material Selection

Durability is a critical aspect of UV aging chambers, as prolonged exposure to UV radiation and moisture can degrade inferior materials. High-grade stainless steel or corrosion-resistant alloys are commonly used for chamber interiors, while insulated exteriors minimize heat loss and energy consumption. Seals and gaskets made from UV-resistant polymers prevent leaks and maintain consistent environmental conditions.

5. Validation and Performance Testing

Reputable manufacturers subject their chambers to rigorous validation tests before delivery. These include uniformity checks for irradiance, temperature distribution, and humidity levels across the test area. Third-party certification from accredited laboratories further verifies compliance with claimed specifications, reinforcing product credibility.

Industry Applications and Reliability

UV aging test chambers serve diverse industries by predicting material behavior under accelerated weathering conditions.

- Automotive: Evaluating the resistance of paints, seals, and interior components to sunlight and humidity ensures long-term performance in harsh environments.

- Construction: Testing roofing materials, sealants, and polymers for UV stability prevents premature degradation in outdoor applications.

- Textiles and Coatings: Assessing colorfastness and structural integrity under UV exposure helps manufacturers develop fade-resistant products.

The ability of these chambers to deliver consistent, repeatable results hinges on their design and manufacturing quality. Variations in irradiance, temperature, or humidity can lead to misleading data, underscoring the necessity for precision engineering.

Selecting a High-Quality UV Aging Test Chamber

When procuring a UV aging chamber, several considerations ensure optimal performance:

- Manufacturer Reputation: Established providers with a history of delivering reliable equipment are more likely to offer robust warranties and post-sale support.

- Customization Options: Chambers adaptable to specific testing protocols (e.g., cyclic condensation, spray functions) enhance versatility.

- Service and Maintenance: Availability of spare parts, calibration services, and technical support prolongs equipment lifespan and maintains accuracy.

The quality of UV aging test chambers is demonstrably assured through adherence to international standards, precision engineering, and rigorous validation processes. Industries reliant on accelerated weathering tests must prioritize equipment that delivers consistent, accurate results to safeguard product performance and compliance. By selecting chambers from reputable manufacturers and maintaining strict operational protocols, organizations can ensure long-term reliability in their material testing programs.