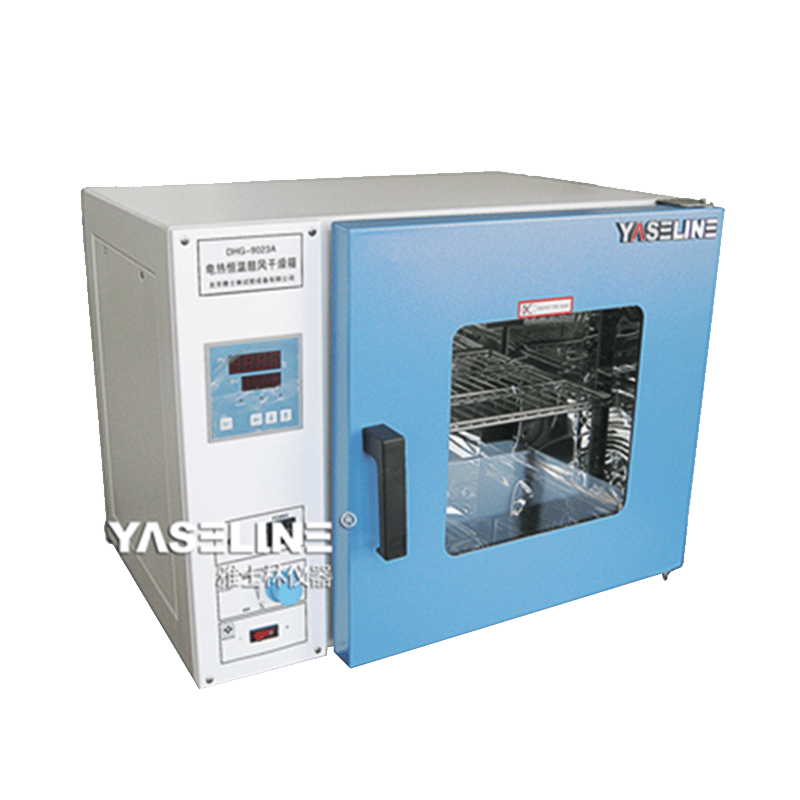

yashilin Instrument Environmental Testing Manufacturer suggests considering the following aspects when selecting a vacuum drying oven to enhance research efficiency:

-

Identify Requirements: First, understand your specific needs, including the types and quantities of samples, as well as the required drying time and temperature. Based on these requirements, determine the specifications and model of the vacuum drying oven.

-

Brand Reputation: Choose a manufacturer or brand with a strong reputation to ensure product quality and after-sales service.

-

Performance Parameters: Pay attention to the performance parameters of the vacuum drying oven, such as maximum temperature, vacuum level, heating rate, and temperature control accuracy. Select a product that meets your needs.

-

Ease of Operation: The operation of the vacuum drying oven should be straightforward, with a clear control panel for user convenience.

-

Safety: Opt for a vacuum drying oven that complies with safety standards, including features like explosion-proofing and over-temperature protection, to ensure safety during use.

-

Price: Price is also an important factor when selecting a vacuum drying oven. Choose a product that fits your budget.

Selecting a vacuum drying oven should be based on research needs, with comprehensive consideration given to materials, control systems, additional features, and after-sales service to improve research efficiency.