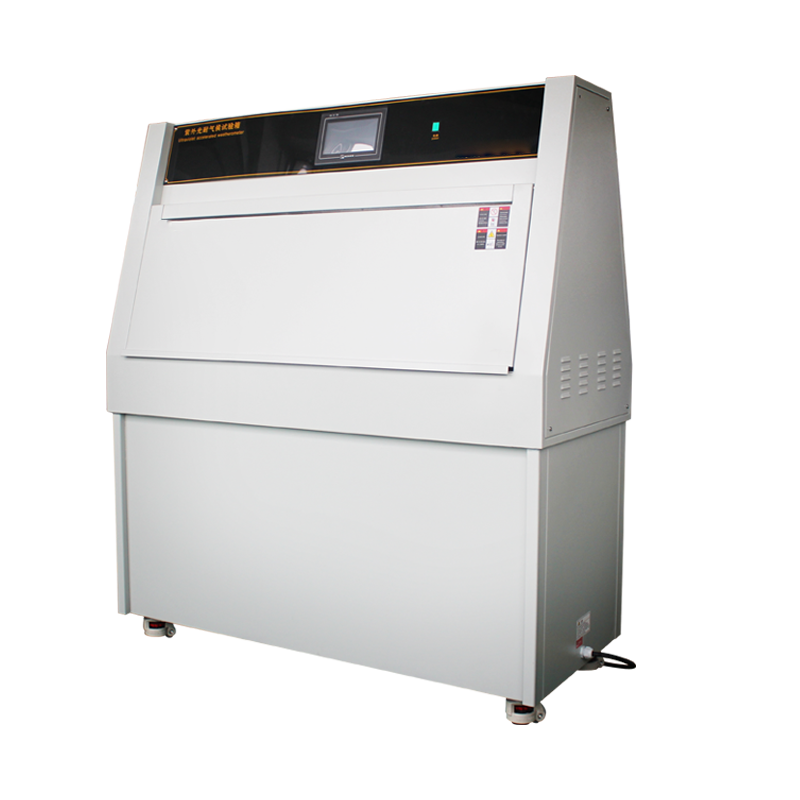

UV aging chambers can replicate the damage caused by sunlight, rain, and dew, reproducing in just days or weeks the harm that would take months or years outdoors. These chambers expose materials to alternating cycles of UV light, controlled humidity, and high temperatures. Special fluorescent UV lamps simulate sunlight exposure, while condensation and/or water spray simulate dew and rain.

The primary function of UV aging chambers is to detect whether product materials exhibit issues such as fading, discoloration, loss of gloss, chalking, cracking, cloudiness, embrittlement, reduced strength, or oxidation.

Additionally, they reproduce the destructive effects of rain and dew. UV aging test chambers expose samples to controlled cycles of simulated sunlight and moisture, combined with elevated temperatures. (UV fluorescent lamps mimic sunlight, while condensation or spray systems replicate moisture effects.)

Common Standards for UV Aging Chambers Include:

- GB 9271-2008 – Paints and varnishes – Standard panels

- GB/T 12967.4-1991 – Anodizing of aluminium and aluminium alloys – UV resistance of coloured anodic oxidation coatings

- GB/T 16422.3-2014 – Plastics – Methods of exposure to laboratory light sources – Part 3: Fluorescent UV lamps

- GB/T 23987-2009 – Paints and varnishes – Artificial weathering of coatings – Exposure to fluorescent UV lamps