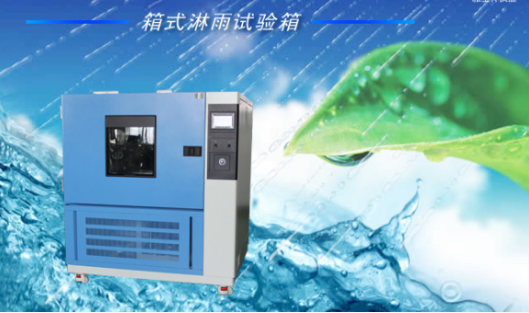

Every rainy season, issues like water-damaged electronics and leaking outdoor equipment frequently make headlines, as consumers grow increasingly demanding about waterproof performance. Whether it’s smartphones, smartwatches, new energy vehicles, or outdoor lighting, waterproof capability has become a critical benchmark for product quality. In this context, water spray test chambers—acting as the "gatekeepers" of waterproof performance—are emerging as essential tools for manufacturing upgrades.

Putting Products to the Test with Precision

Water spray test chambers simulate various rainfall intensities, subjecting products to comprehensive "trials." Their core advantage lies in accurately replicating real-world conditions: the equipment can adjust rainfall intensity, water spray angles, and even wind speed, covering international waterproof rating standards from IPX1 to IPX8—from light drizzles to torrential downpours, vertical sprays to angled jets. For example, automotive lighting must endure continuous water spray to ensure sealing integrity, while outdoor cameras undergo extreme rain simulations to verify circuit board protection.

Data-Driven Product Improvement

Equipped with high-precision sensors, these chambers record critical parameters in real time, such as water ingress points and leakage duration. One electronics manufacturer discovered that an outdoor speaker was prone to leaks at the interface under specific spray angles. Engineers then optimized the sealing ring design, elevating its waterproof rating from IPX4 to IPX6 and successfully passing a heavy rain simulation.

Faster R&D, Shorter Iteration Cycles

Traditional waterproof testing relies on natural conditions, which are time-consuming and inconsistent. Water spray test chambers can simulate months of rainy conditions in just 24 hours, allowing companies to validate designs rapidly. A home appliance brand used this technology to slash waterproof testing time for a new water heater from 30 days to just 7 days, gaining a market lead and achieving a 20% sales boost.

Beyond Durability—A Commitment to Quality Living

Breakthroughs in waterproof performance aren’t just about product longevity—they reflect consumers’ expectations for premium quality. Like a strict "examiner," water spray test chambers use scientific data to set quality benchmarks, driving the steady evolution of "Made in China" into "Quality Crafted in China."