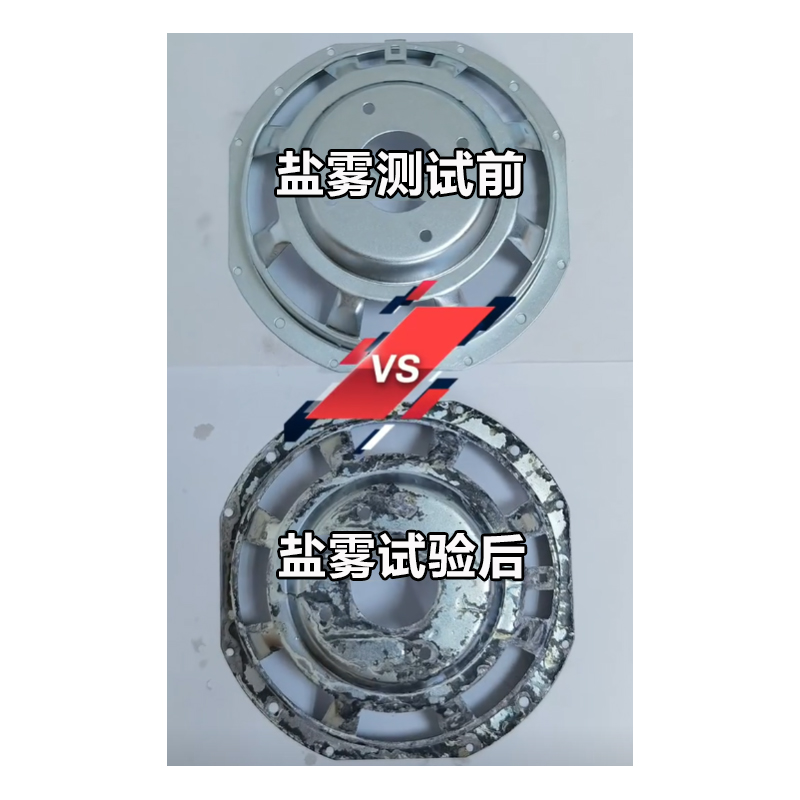

The uniformity of the spray distribution in a salt spray corrosion test chamber is a decisive parameter that directly affects the validity, reproducibility, and comparability of corrosion test results. The performance of coatings, metallic substrates, fasteners, electronic components, and protective treatments can only be accurately assessed when the test environment is controlled with a high degree of precision. A non-uniform salt fog field will result in localized deviations, leading to false positives or negatives, and may compromise the credibility of laboratory reports. For this reason, systematic evaluation of spray uniformity has become a technical requirement for manufacturers, research institutions, and quality assurance laboratories.

Importance of Spray Uniformity in Corrosion Testing

The corrosion process is influenced by several variables: droplet size distribution, concentration of sodium chloride, pH value, air pressure stability, and most critically, the spatial uniformity of the mist inside the test chamber. If one specimen is exposed to higher accumulation of droplets compared to another, the comparative degradation rates become meaningless. International standards such as ASTM B117, ISO 9227, and JIS Z 2371 stipulate that the salt fog must be distributed uniformly within the exposure zone, with strict control of collection rates. Achieving this requires not only careful design of the atomization system but also consistent monitoring and calibration during operation.

Key Indicators for Uniformity Assessment

-

Sedimentation Rate Consistency

The most authoritative method to verify spray uniformity is by measuring the sedimentation rate of the salt solution across different positions within the chamber. Standard glass collection funnels are positioned at various points. After a specified exposure time, the volume of collected solution is compared. The difference between the maximum and minimum values must remain within the tolerance specified by international standards, typically ±15% of the mean value. -

Droplet Size Distribution

Uniform droplet size ensures consistent wetting of specimen surfaces. Large droplets may cause run-off, while excessively fine aerosols may evaporate before deposition. Optical particle analysis and microscopic inspection are used to determine whether droplet sizes remain within the ideal range of 1–10 micrometers. Uniformity in this parameter guarantees equal exposure to corrosive media across all surfaces. -

Chamber Airflow Dynamics

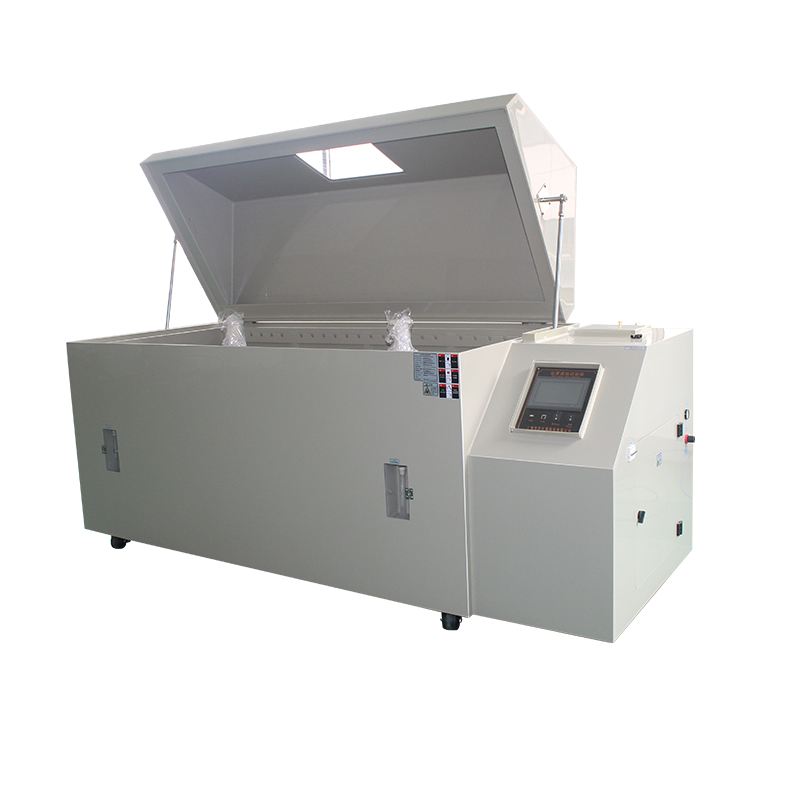

The internal design of the chamber—including air diffuser systems, nozzle orientation, and chamber volume—directly influences how the mist is dispersed. Uneven airflow patterns can cause accumulation in corners or on specific specimen racks. Computational fluid dynamics (CFD) simulations are increasingly employed to optimize spray paths, ensuring that turbulent dead zones are eliminated. -

pH Stability of Collected Solution

Even if sedimentation volume is consistent, the chemical stability of collected droplets must also be verified. pH drift between collection points indicates localized differences in evaporation or condensation. High-quality test chambers incorporate precision atomizers and solution heating systems that maintain stable chemistry, thereby ensuring reliable uniformity. -

Visual Fog Density Observation

Although qualitative, visual assessment remains a useful supplementary technique. Uniform fog density throughout the chamber indicates proper atomization and circulation. Skilled operators can detect non-uniform spray patterns by observing droplet trails, localized condensation, or clear zones within the exposure area.

Testing Procedures for Uniformity Verification

To verify spray uniformity, internationally recognized protocols are followed:

-

Preparation of Standard Salt Solution

Sodium chloride of analytical grade is dissolved in deionized water, typically at 5% by mass. Conductivity and pH are adjusted according to the governing test standard. -

Positioning of Collection Funnels

Standardized funnels with a known collection area are distributed across the chamber, including near corners, center, and specimen shelves. -

Collection Period

The chamber operates under normal test conditions for a specified period, often 16 hours, to allow sufficient accumulation of solution. -

Measurement of Collected Volume

The collected liquid is measured using calibrated graduated cylinders. Results are documented for each position. -

Calculation of Uniformity Index

The deviation between maximum and minimum collection rates is calculated as a percentage of the mean. Compliance with ASTM B117 requires that the collection rate falls within 1.0 to 2.0 mL/h for each funnel, with deviations not exceeding ±15%.

By following this method, laboratories confirm whether the chamber achieves the necessary level of uniform spray distribution.

Engineering Factors Influencing Spray Uniformity

-

Nozzle Design and Material

Atomization nozzles are the core of spray generation. High-precision, corrosion-resistant nozzles made from specialized glass or PTFE ensure stable droplet formation over long operating periods. Inferior materials wear quickly, resulting in irregular spray patterns. -

Air Pressure Regulation

Compressed air must be filtered, humidified, and stabilized before entering the nozzle. Pressure fluctuations cause changes in droplet velocity and size. Advanced chambers employ precision regulators and monitoring sensors to maintain pressure within ±0.01 MPa. -

Solution Pre-heating and Constant Temperature Control

Temperature differences between the salt solution and the chamber environment can lead to uneven evaporation and droplet condensation. Pre-heating systems ensure that atomized solution matches chamber temperature, thereby enhancing uniformity. -

Chamber Geometry and Specimen Loading

Overcrowding the chamber with specimens disrupts airflow. High-quality chambers provide optimized internal layouts that balance specimen capacity with uniform distribution of mist. -

Maintenance and Cleaning

Regular cleaning of nozzles, pipelines, and collection devices prevents salt crystallization, which can distort spray characteristics. Preventive maintenance protocols are essential to sustaining long-term performance.

Role of Technology in Enhancing Uniformity

Modern salt spray chambers integrate advanced technologies to ensure superior spray uniformity:

-

Automated Monitoring Systems

Sensors continuously measure sedimentation rates, droplet size, and chamber humidity, with real-time feedback to operators. -

Data Logging and Traceability

Electronic systems record uniformity data, allowing traceable compliance with quality standards and audit requirements. -

Intelligent Control Algorithms

Microprocessor-based controllers automatically adjust airflow, pressure, and temperature to stabilize spray distribution, even under varying external conditions. -

Modular Atomization Systems

Multi-nozzle configurations enable tailored spray fields for large or irregular chamber volumes, ensuring that no area is under-exposed.

Advantages for Manufacturers and Laboratories

Consistent spray uniformity brings measurable benefits:

-

Reliable Test Results

Accurate performance evaluation of coatings, materials, and assemblies leads to higher confidence in product reliability. -

Compliance with International Standards

Meeting ASTM, ISO, and JIS requirements ensures that test data are recognized globally. -

Reduced Risk of Disputes

Uniform spray distribution minimizes inconsistencies that could be challenged in supplier–customer relationships. -

Enhanced Brand Reputation

Laboratories and manufacturers using advanced, uniform test chambers demonstrate technical competence and quality assurance capability.

The ability to determine whether the spray of a salt spray corrosion test chamber is uniform is not merely a technical detail but a fundamental criterion for ensuring the validity of corrosion testing. By applying systematic assessment methods—sedimentation rate measurements, droplet size analysis, airflow evaluation, and chemical stability checks—operators can guarantee that specimens are exposed to identical conditions. Engineering refinements, advanced monitoring technologies, and strict maintenance regimes further enhance uniformity. For organizations seeking reliable, internationally recognized test results, investing in high-precision salt spray chambers with proven uniformity performance is a strategic decision that safeguards product quality, compliance, and market competitiveness.