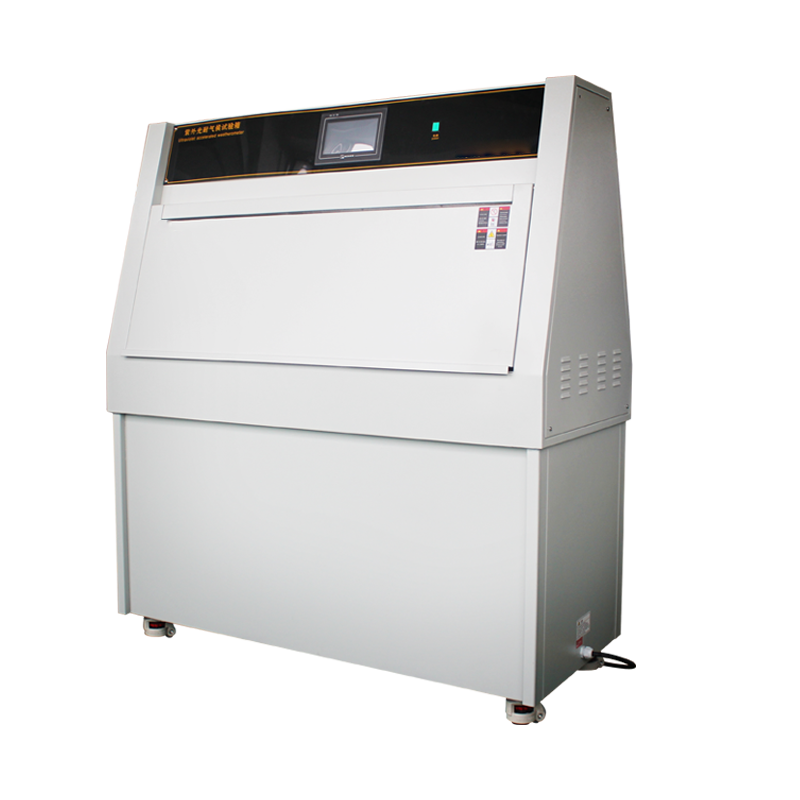

In modern industrial manufacturing and product development, material durability and resistance to light aging have become critical considerations. To ensure product performance in real-world conditions, UV aging test chambers have been developed. These chambers are primarily used to simulate and accelerate the degradation process of materials under sunlight exposure, allowing for the evaluation of their long-term performance.

Key Purposes of a UV Aging Test Chamber

-

Simulating Natural Environmental Conditions

The primary purpose of a UV aging test chamber is to replicate natural sunlight, including ultraviolet (UV) rays, visible light, and heat, to assess material durability under prolonged exposure. This is crucial for monitoring the performance of plastics, coatings, rubber, and other materials. -

Accelerating the Testing Process

Compared to long-term outdoor exposure testing, UV aging chambers can rapidly accelerate material aging in a controlled environment. This enables companies to obtain performance data quickly, significantly reducing product development cycles.

-

Providing Reliable Data Support

Through systematic testing, companies can accurately evaluate a material's UV resistance, color fading, strength loss, and other performance changes. This data serves as a scientific basis for material selection and product design. -

Enhancing Product Quality

By using UV aging test chambers, manufacturers can identify potential quality issues and defects before products enter the market. This improves product reliability, reduces failure risks caused by material degradation, and strengthens consumer trust. -

Meeting Industry Standards

Many industries impose strict requirements on material light resistance. UV aging test chambers help companies comply with standardized testing protocols, ensuring products meet industry regulations and enhancing market competitiveness.

The UV aging test chamber is an indispensable testing tool designed not only to simulate and accelerate material aging but also to ensure product quality, improve R&D efficiency, and meet industry standards. In today’s highly competitive market, businesses must prioritize material durability testing to guarantee long-term stability and reliability. Choosing a UV aging test chamber is a crucial step toward ensuring product excellence and gaining a competitive edge.