In modern industry and electronic product development, the rain test chamber serves as a crucial testing tool, playing a vital role. It not only simulates various environmental conditions but also provides comprehensive evaluation and verification of a product's waterproof performance. Today, let’s delve into the waterproof ratings of rain test chambers and their significance in product testing.

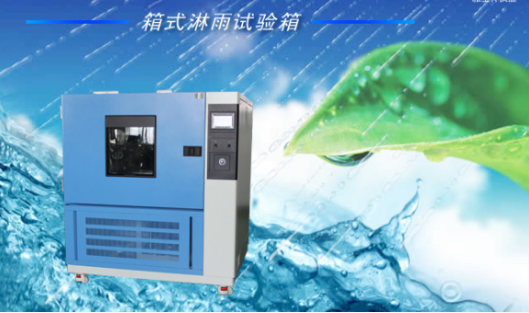

What is a Rain Test Chamber?

A rain test chamber is a specialized device designed to evaluate how products perform in rainy environments. By simulating rainfall of varying intensities and angles through spraying or showering, it assesses the waterproof capabilities of products. This type of testing is widely used in fields such as electronic devices, automotive components, and household appliances to ensure products can function normally even in harsh weather conditions.

Classification of Waterproof Ratings

Waterproof ratings are typically classified according to standards set by the International Electrotechnical Commission (IEC), with the most commonly used being the IP (Ingress Protection) rating. The IP rating consists of two digits: the first indicates dust resistance, while the second denotes waterproof performance. For rain test chambers, the focus is primarily on the second digit, which represents waterproofing.

- IPX1: Harmless against vertically falling drops of water. Suitable for products in general environments.

- IPX2: Harmless against water drops when tilted up to 15 degrees. Suitable for products exposed to minor dripping.

- IPX3: Harmless against spraying water. Suitable for devices that may encounter water sprays.

- IPX4: Harmless against splashing water from all directions. Ideal for products requiring protection against general water splashes.

- IPX5: Harmless against low-pressure water jets. Suitable for use in environments with stronger water flow.

- IPX6: Harmless against powerful water jets. Suitable for outdoor equipment.

- IPX7: Harmless against short-term immersion in water. Capable of withstanding temporary submersion.

- IPX8: Harmless against prolonged immersion in water. Designed for underwater equipment.

The Importance of Waterproof Rating Testing with Rain Test Chambers

- Validates Product Design Rationality: Rain testing helps companies identify potential waterproof weaknesses, allowing for timely design improvements to prevent performance failures caused by water ingress.

- Enhances Market Competitiveness: Products with higher waterproof ratings earn greater consumer trust and elevate brand reputation.

- Complies with Regulations and Industry Standards: Different industries have strict requirements for product IP ratings, and rain testing ensures compliance.

- Reduces Post-Sale Risks: Early detection of waterproof issues minimizes the risk of repairs and returns due to water damage.

Why Choose a Rain Test Chamber?

Opting for a rain test chamber for waterproof testing offers multiple advantages:

- Ensures Product Quality: Rigorous waterproof testing guarantees product reliability in real-world conditions, reducing customer complaints related to water damage.

- Boosts Competitiveness: Helps companies establish a strong brand image and enhances consumer confidence in their products.

- Meets Regulatory Requirements: Many industry standards and regulations specify waterproof performance criteria, and rain test chambers assist companies in achieving certification.

Conclusion

Rain test chambers play an indispensable role in evaluating the waterproof performance of products. By gaining a deeper understanding of their waterproof ratings and testing processes, companies can better control product quality and enhance market competitiveness. If you are still searching for a suitable waterproof testing solution, we invite you to explore our rain test chambers—empowering you to develop high-quality products that stand out in the market!