With the advancement of technology and improvements in people’s quality of life, the demands for product performance and quality are increasingly high. During the production process, products often need to withstand various environmental challenges, and corrosion is a significant issue that cannot be overlooked. In marine environments, disaster-prone areas, and industrial settings, corrosion problems are particularly prominent. To ensure product quality and reliability, manufacturers need to identify and address these issues promptly. Therefore, the salt spray corrosion test chamber has been widely used for corrosion testing of products.

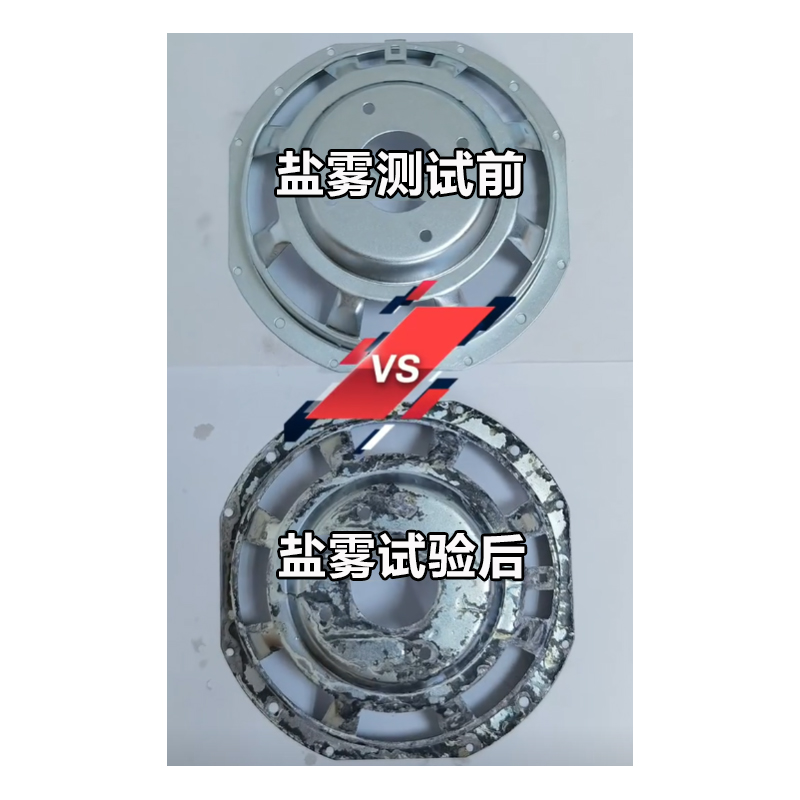

The salt spray corrosion test chamber is a device that simulates a marine environment, enabling producers to quickly test a large number of products in a short time and conduct comprehensive corrosion resistance tests before the products leave the factory. During testing, the chamber sprays a corresponding liquid to simulate the salt spray corrosion found in marine environments, allowing for the evaluation of product performance under such conditions. Through testing in the salt spray corrosion test chamber, manufacturers can discover potential corrosion issues in marine environments early, facilitating timely optimization and improvements to ensure product quality and reliability. Moreover, the data obtained from these tests are scientific and reliable, providing effective data support for quality control.

The salt spray corrosion test chamber offers advantages of time-saving, labor-saving, and peace of mind, reducing production costs and personnel expenses while increasing production efficiency and product quality. First, the chamber features a high level of automation; producers only need to set the appropriate experimental parameters and let the device operate autonomously. Second, the chamber can test multiple products simultaneously, and the observation duration can be set according to requirements. Lastly, it provides quick and accurate test data, as well as detailed analysis of test results, helping producers quickly identify the root causes of any product issues and take timely measures for optimization and improvement.

The applications of the salt spray corrosion test chamber are extensive, covering industries such as automotive, rail, electronics, aviation, and shipbuilding. For example, the automotive industry needs to test the corrosion resistance of vehicle bodies and components. The electronics industry must assess the corrosion resistance of electronic components in marine environments. Additionally, the aviation and shipbuilding sectors require testing of the durability of aircraft and ship components in marine conditions. Therefore, the salt spray corrosion test chamber has become an indispensable piece of equipment in modern manufacturing and product inspection.

In summary, the salt spray corrosion test chamber is a specialized, time-saving, labor-saving, and worry-free device suitable for corrosion testing of products across various industries. It helps manufacturers timely discover corrosion issues in their products, providing robust assurance for product quality. This will positively impact the long-term development and brand building of manufacturers.