In modern industrial production, product durability and reliability are among the key factors for a company's success. As market competition intensifies, consumer demands for product quality continue to rise. Therefore, businesses must adopt effective measures to ensure their products perform well under various environmental conditions. UV aging test chambers, as essential testing equipment, have become a critical tool for evaluating product durability due to their unique functions and applications.

1. Working Principle of UV Aging Test Chambers

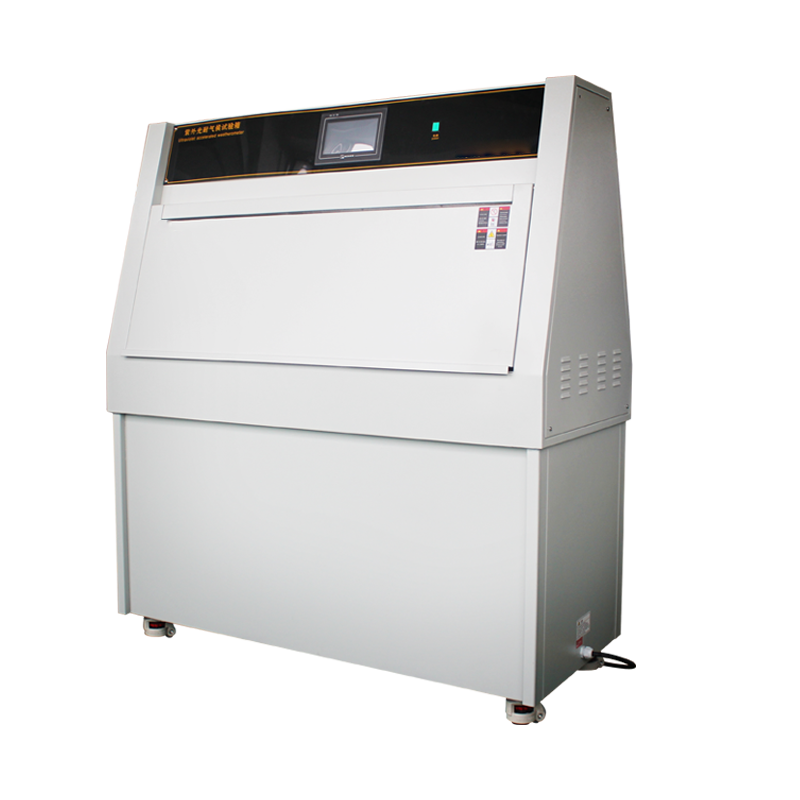

UV aging test chambers simulate ultraviolet (UV) radiation in natural environments by using specific wavelengths of UV light to accelerate the aging process of materials and products. Environmental factors such as temperature and humidity inside the chamber can also be controlled to replicate various real-world conditions. By exposing products to prolonged UV radiation, companies can assess their durability and stability over long-term use.

2. Core Value in Ensuring Product Quality

Early Identification of Potential Issues

UV aging test chambers help companies detect potential quality problems before products are officially launched. By simulating UV exposure, issues such as material fading, brittleness, and cracking can be identified, allowing for timely material improvements or design optimizations and reducing the risk of product recalls.

Enhancing Product Competitiveness

Products tested in UV aging chambers often exhibit better weather resistance and stability, directly boosting their market competitiveness. Consumers are more inclined to choose products that have undergone rigorous testing and demonstrate high durability, thereby strengthening brand reputation and market share.

Compliance with Industry Standards and Regulations

Many industries have clear standards and requirements for product durability. By using UV aging test chambers, companies can ensure their products meet relevant quality standards and regulatory requirements, avoiding legal liabilities and financial losses due to non-compliance.

Optimizing Material Selection

By conducting UV aging tests on different materials, companies can better understand how various materials perform under UV exposure, enabling them to optimize material choices. This not only improves product performance but also reduces production costs and enhances material efficiency.

Promoting Sustainable Development

Ensuring product durability allows companies to minimize resource waste caused by product failures, contributing to sustainable development. Highly durable products reduce the frequency of replacements for consumers and lower raw material consumption during production, aligning with current societal emphasis on environmental protection.

As an effective tool for ensuring product durability, the core value of UV aging test chambers lies in their ability to identify potential issues, enhance product competitiveness, ensure compliance with industry standards, optimize material selection, and promote sustainable development. With advancements in technology and evolving market demands, UV aging test chambers will play an increasingly vital role in product development and quality control. Companies should fully leverage this tool to provide consumers with higher-quality, more durable products, thereby securing an unbeatable position in the competitive market.