Coating materials are widely used in industrial fields such as automotive, aerospace, and construction, where their performance directly affects product quality and service life. Salt spray corrosion is one of the most common forms of degradation for coatings, making it essential to evaluate their performance under salt spray conditions. As a device that simulates salt spray environments, salt spray test chambers are extensively employed in the assessment and research of coating material properties.

1. Principle and Testing Methods of Salt Spray Test Chambers

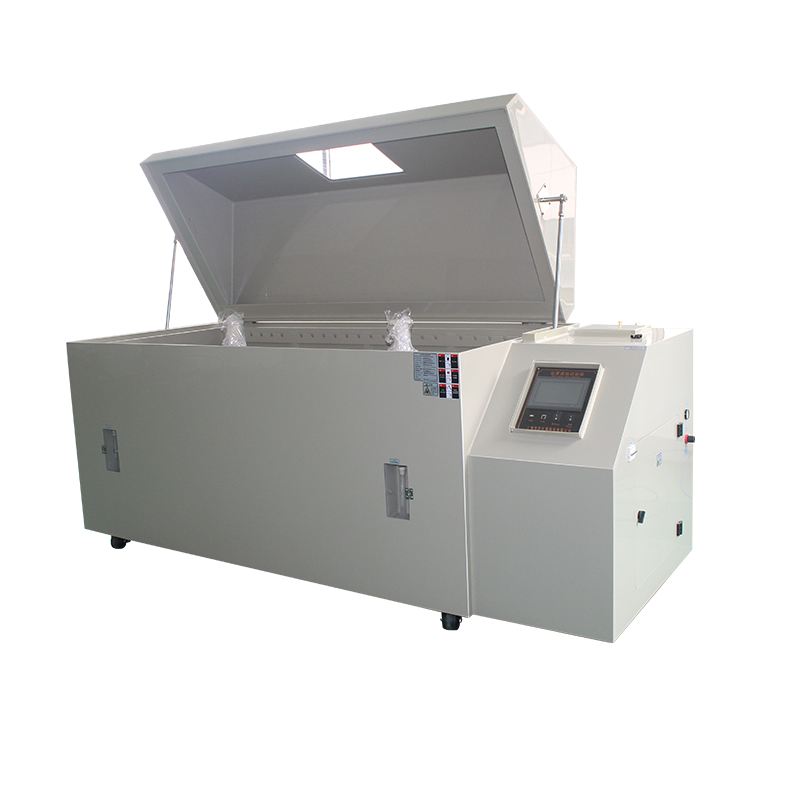

Salt spray test chambers conduct accelerated corrosion testing on coating materials by simulating salt spray environments. The principle involves generating a salt spray solution and spraying it onto the sample surface to replicate real-world salt spray corrosion processes. Common testing methods include continuous spray and cyclic spray tests, which simulate different salt spray corrosion conditions to evaluate coating performance.

2. Performance Evaluation of Coating Materials Using Salt Spray Test Chambers

Salt spray test chambers enable quantitative assessment of coating materials' corrosion resistance, including metrics such as corrosion rate, corrosion morphology, and extent of degradation. By conducting tests in salt spray chambers, the corrosion resistance of coatings under salt spray conditions can be evaluated, providing critical insights for product design and material selection.

In conclusion, salt spray test chambers play a vital role in evaluating coating material performance by simulating real-world salt spray corrosion and providing quantitative data. Therefore, they hold significant importance for coating material research and quality control, warranting further in-depth study and application.