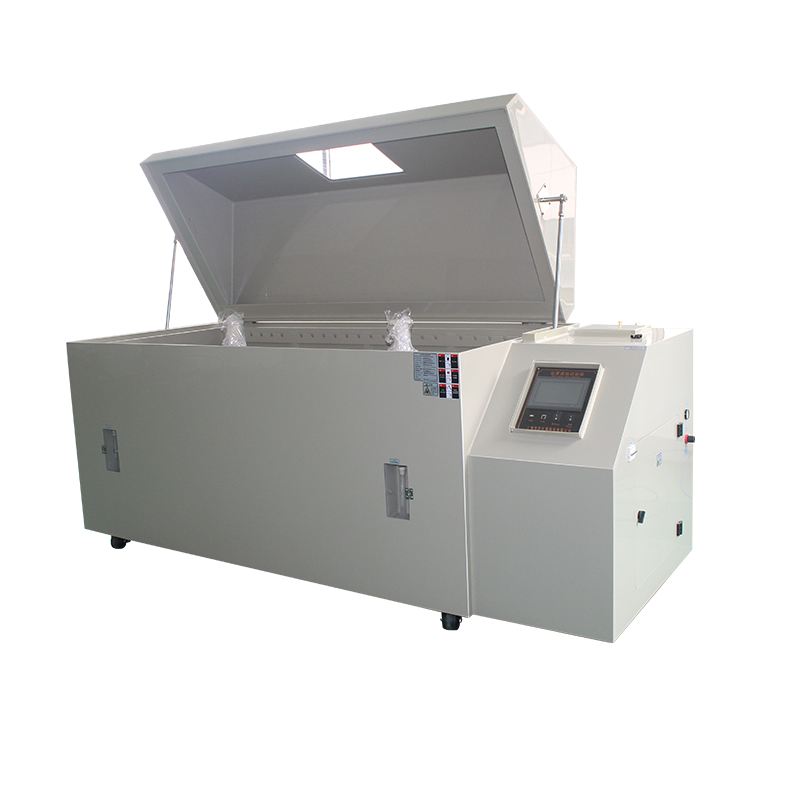

Based on our years of sales and after-sales service experience, we have summarized several common issues in salt spray test chambers where inaccurate data allocation leads to deviations between test results and actual conditions. Factors such as the saltwater ratio, test temperature, spray volume, and water quality can all affect the accuracy of test results. But don’t worry—we’ll guide you on how to resolve these problems.

The Neutral Salt Spray (NSS) Test is currently the most widely used accelerated corrosion test method. The standard saltwater ratio is 50g of salt dissolved in 1L of solution, with a salt-to-water ratio of approximately 1:19 (1/20 concentration). The pH of the saltwater should be between 6 and 7 to meet requirements. Sometimes, customers miscalculate the ratio, leading to deviations in test results. Therefore, we recommend using pH test strips to verify the solution’s pH.

The test temperature in a salt spray chamber should be maintained at around 35°C, while the saturation tower temperature should be kept at approximately 47°C. These temperature settings must not be mixed up. Of course, the precision and accuracy of the temperature controller are crucial.

The salt spray settlement rate is also critical. According to international standards, the required spray rate is 1–2 mL per hour over an 80 cm² area. If the spray volume is too high or too low, simply adjust the spray tower’s height to correct the issue.

For any test chamber, water quality plays a significant role in the test outcome. Therefore, purified or distilled water should be used when preparing the salt solution. Some customers use tap water directly, but it contains chemicals and impurities that can distort test results and clog the nozzles, preventing proper spray operation.